Butterfly Valve

A Butterfly Valve is a quarter-turn rotational motion valve used to stop, regulate, and start fluid flow. It features a disc mounted on a rotating shaft that opens or closes the flow path in the pipe. Its compact design, ease of operation, and versatility make it suitable for a wide range of industries, including water distribution, wastewater treatment, chemical, oil, and gas.

Key Features and Advantages:

1. Compact Design:Butterfly valves are lightweight and require less space compared to other types of valves, such as gate or ball valves.

2. Quick Operation:The quarter-turn mechanism allows for fast opening and closing.

3. Low Maintenance:Due to their simple design and fewer moving parts, butterfly valves are relatively low maintenance.

4. Cost-Effective:Typically more affordable than other types of valves due to simpler construction and lighter materials.

5. Versatility:Available in various materials and designs to suit a wide range of applications, including high-pressure, high-temperature, and corrosive environments.

6. Pressure Drop:Butterfly valves generally have a lower pressure drop compared to gate valves when fully open, especially in larger diameters.

7. Flow Regulation:While butterfly valves are primarily used for on/off control, they can also be used for throttling or flow regulation.

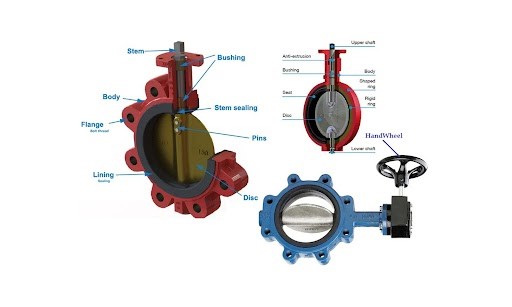

Construction of a Butterfly Valve:

1. Valve Body:

• Material: The valve body is typically made from materials like cast iron, ductile iron, carbon steel, or stainless steel, depending on the application.

• Design: The body is designed to fit between two pipe flanges (wafer type) or to be bolted on (lug type). Some butterfly valves also have flanged ends for easy installation.

2. Types:

• Wafer Type: Positioned between two pipe flanges and held by bolts.

• Lug Type: Has threaded inserts (lugs) that allow the valve to be bolted directly into the pipe.

• Flanged End Type: In a standard configuration to provide ease of installation

3. Material:

The disc, which controls flow, is usually made from stainless steel, ductile iron, aluminium bronze, or other coated metals for corrosion resistance.

4. Design:

The disc is located in the center of the valve body and rotates to open or close the valve. In an open position, the disc allows fluid to flow through. When rotated 90 degrees, it closes off the flow.

5. Offset Types:

o Concentric (Zero-Offset) Butterfly Valve:

• The disc is positioned in the center of the valve body, with the stem passing through the center of the disc.

• Ideal for low-pressure applications with soft seats.

• Commonly used for water and wastewater applications.

o Double Offset (High-Performance Butterfly Valve):

• The disc is offset from the center of the body and the shaft axis, reducing seat contact during operation and increasing seal life.

• Suitable for higher pressures and temperatures than concentric valves.

• Used in industries like oil and gas, power generation, and chemical processing.

o Triple Offset Butterfly Valve:

• Has three offsets (two like a double offset valve, with an additional third angular offset).

• This design ensures a metal-to-metal seal with minimal wear, making it ideal for high-temperature, high-pressure, and critical applications.

• Used for steam systems, petrochemical, and process industries.

6. Operation:

o Manual:

Operated by a lever or gear system for smaller valves.

o Automated:

Larger valves or those in hard-to-reach areas are typically equipped with electric, pneumatic, or hydraulic actuators for remote or automated control.