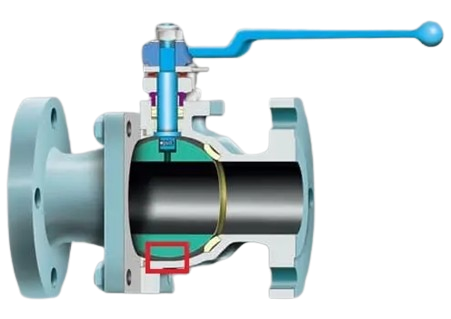

Floating Ball Valve

Floating ball valves are made by linking a ball to the step, leaving the bottom part to flow freely. Unlike trunnion ball valves, components in a floating one can flow freely, ensuring a high degree of flexibility. Floating ball valves have set rings which are essential for holding it intact. The big difference between the two is that floating ones are dual-directional, thus requiring high torque forces.

Pros

• Responsive: Floating ball valve is responsive to fluid flow, allowing flexibility in operations.

• Small-scale applications: Due to their size, it is extremely beneficial to use them even in small-scale operations. Floating ball valves are an efficient option to choose when the operations tend to be in the lower range.

Cons

• High torque: The incentive in managing high torque focus is quite high, making it an expensive option.

• High pressure: Floating ball valves possess high pressure during shut-off situations and are highly prone to damage.

Applications

• Emergency shut-off systems: Their highly responsive characteristic makes them an excellent choice for emergency systems. As floating ball valves are unmounted and not welded together, they can be a suitable option for the flow of fluids like fuels and water.

• Water distribution: Water systems often require the prevention of air pockets and smooth water distribution. They require optimal pressure levels and good controlling factors to withstand high forces. Due to the pressure-sensitive nature of floating ball valves, they are an ideal type of valve for handling high water flow.